As pioneers of the mat industry, we’ve developed several types of mats to meet the various needs of different industries. What you see listed below are our main types of mats, as we call them, but you may know them by another name. If you’re looking for truck mats, composite mats, or oak bog mats, you’ll see that we provide just that with our line of products. Trust in our mats, since we perfected and patented our interlocking mat design we’ve been producing the same product ever since. That’s how you know it works.

OILFIELD INTERLOCKING MATS

Our Patented oilfield interlocking mats are 3-ply laminated wooden mats that are manufactured by assembling 3 layers of wood boards into a mat with unique features that allow adjoining mats to overlap and interlock. The boards are affixed with nails and/or bolts to create a strong durable unit. The mat that changed the oil industry overnight!

The interlocking patented oilfield mat gave the industry an efficient solution to access challenges in remote locations and environmentally sensitive areas.

Before we patented and introduced mats in the mid-1970’s, operators were forced to build up road beds with countless loads of fill material. Then they faced the expensive proposition of installing a road surface with either aggregates or the labor intensive process of laying individual lumber boards side by side until a suitable surface was created. Projects Interlocking mats allow operators to build temporary roadways that can be easily installed (and removed) within 2 to 3 days, not months as in the past. The unique interlocking patented feature allows the mats to distribute loads across large areas, reducing the damage to subsoils and offering a stable consistent work surface for vehicles and equipment. The result is a safe, uniform and stable work surface.

Patent No. 4,462,712 / Patent No. 5,822,944

RIG MATS

The foundation for success.

Rig Mats are constructed with a steel I-beam frame, cross members and internal wood filler. The mat interlock on the ends and can be used as skids on project sites.

We’ve taken our 40-plus years of industry experience and expertise and partnered with Modern Manufacturing in manufacturing and marketing of rig mats for all your drilling and construction needs. Modern’s manufacturing techniques are industry leading; exceeding US standards in quality control.

FEATURES

The average life of a rig mat is 10 years, but if constructed soundly, it can stay active for 15 to 20 years. Our steel frame rig mats are made with W6 x 15# I-beam cross members unlike other mats made with flat bar cross members. The 8’ x 20’ and 8’ x 40’ rig mats consist of independent wood sections made up of rough cut 2” x 6” treated pine nailed together for superior rigidity. The mats are versatile and ideal for everything from large construction sites to camp sites.

MAT OPTIONS (Customizing Available)

2”x6” or 6”x6” horizontally placed treated wood cross members · Oak cross members · Size up to 12’ wide and 60’ long· Additional reinforced lifting slots

· Boxed sides · Additional surface treatment · End cap ramps · Additional longitudinal beams – Interlocking feature on each end – Skid frame – Largest inventory in the USA (new and used, sale or rent) – Custom sizes

CRANE & PIPELINE MATS

Crane and pipeline mats are mats manufactured from rough sawn timbers in varying lengths that are affixed / bolted side by side with steel tie and/or lifting rods and nuts to make an assembly of timbers into a mat.

Hard wood. Hard working.

Since the early 1970’s, the Global Mat family has been manufacturing the highest grade crane mats available in the market with specifications that far exceed any competitor’s products.

Our crane mats are built from mixed American hardwoods and come in 8” to 16” thick, and up to 40’ long. Each mat is constructed with steel rods on four foot centers, impact- wrench tightened, countersunk, cut off, and bradded to ensure that nuts are retained throughout the life of the mat. Special care is taken in that the mat is dense and compression resistant to withstand the harshest conditions and heaviest equipment. Crane mats can be manufactured with various lifting options such as exposed bolts or cables to meet your specifications. If you’re looking for the best quality product to stabilize the subgrade or crane during a critical heavy lift, our matting products are the best for the application. Safety Counts!

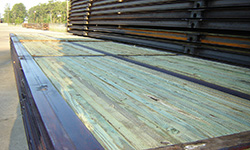

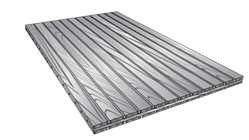

3-PLY LAMINATED MATS

The patented 3-ply laminated wooden mats are manufactured by assembling 3 layers of wood boards into a mat. The boards are affixed with nails and/or bolts to create a strong and durable unit.

Strong. Durable. Versatile.

In need of truck mats, mud mats or construction mats? Our laminated mats are the choice by customers wanting superior material specifications and performances.

Our very popular 3-ply laminated mat is available in 8’ widths and 12’, 14’ and 16 foot lengths with features like lifting chains or cables. These mats are strong, durable, and constructed with the same high-grade materials as our traditional crane mats. With a maximum of 1-1/2’ gaps between boards, this allows for traction and to disperse surface and rainwater, while maximizing the engineered strength of the mat. Offering 24/7 access in all weather conditions. Favored by customers all over the world, these lightweight and highly maneuverable mats are the most frequently requested and used by concrete, utility and general construction contractors. There are scores of uses for our 3 ply-laminated mat including temporary roads, site protection, and stable platforms from which to lift loads and operate equipment.

ECOMATS

Synthetic material. Real benefits.

Eco Mats are manufactured from solid synthetic components that are assembled in a laminating pattern to create a solid mat with unique features that allow adjoining mats to overlap and interlock and embedded lifting rings. The boards are affixed with bolts to create a strong durable unit with similar construction techniques to our standard 3-ply laminated oak mats.

Global Mat has always been passionate about manufacturing cutting-edge ground protection mats, and our synthetic ECOmat is a continuation of our historical success in being an industry leader with new and innovative products.

Specifically engineered and designed for multiple applications, our ECOmats offer benefits far beyond the typical hollow core composite mats out in the industry today. Global has partnered with Modern Manufacturing to offer the best synthetic mat on the market today.

ECOmats mats are solid synthetic material that is non-absorbent without the hollow core of traditional composite mats. A hollow core composite mat can become punctured and the internal void area will transport silts, soils, liquids and chemicals. This presents challenges; transportation cost will increase significantly, decontaminating or cleaning the mat is impossible, and you are susceptible to environmental issues.

Another advantage of ECOmat is that it is segmented. This allows us to construct the mat to almost any size, thickness or diversity of materials. Our aim is to produce a mat that achieves your specific goals through flexibility; ECOmat is not restricted to one size or weight. The solid material offers a durable, high compressive strength mat that will support heavy loads.

ECOmats work well in the petrochemical, utility, general construction and oil field industries while minimizing accidents and providing a safe and stable work surface for heavy equipment and personnel. Embedded lifting D-rings that have been certified for overhead lifting are an added feature that allows any equipment to lift and place the mat. ECO Mats are the only mat in the industry that offers this key feature. Another restriction hollow core mats can’t do.

Patent Pending

PIPE CRADLES

Easily Stacked. Easily deployed.

As the world’s leading supplier of oilfield, rig, crane and pipeline mats, Global Mat knows a thing or two about pipe.

Our pipe cradles are specifically designed to hold the bottom of the pipe at a constant height of 20” off the ground. Manufactured of galvanized steel and a synthetic alignment vee – no wood rot or chemical absorption will occur. They can be stacked or nestled in lots of 10 and can be deployed rapidly with only a forklift - there is no need for additional labor on the ground.

One truckload can transport 270 pipe cradles that will hang 135 joints of pipe and reduce approximately 7 truckloads of cribbing. Resulting in significant cost savings, these pipe cradles are easily stacked, deployed, transported, cleaned and reloaded back on the truck and ready for the next assignment.

Pipe cradles can handle up to 36” OD pipe.

Patent Pending

ENVIRONMENTAL

To conquer project sites with stringent environmental permitting requirements due to terrain, tundra, permafrost, muskeg, wetlands, wildlife habitat, or other factors; Global Mat has your access solution. You’ll satisfy the regulatory environmental requirements while providing a safe productive worksite.

INSTALLATION

Global Mat is recognized as a world leader in mat manufacturing and supply, but we also specialize in the transportation, service, installation and removal of matting systems. Not only does our quick-turn delivery team get your mats to you when you need them, but we install and remove them as well.

Our industry leading crews can routinely install up to 50,000 sq. ft. of mats per day at each location with the field experience to meet any unique site specific challenge.

Our mats allow operators to build temporary roadways that can be easily installed (and removed). Mats distribute loads across large areas, reducing damage to subsoils and offering a stable, consistent base for vehicles and equipment. The result is a quicker, safer, and cleaner job. We have the equipment and resources necessary to get the job done fast and installed right, saving you time and money.

Our operators have installed millions of mats in some of the toughest environments and most challenging terrains the world has to offer, while always taking special precautions to protect sensitive environments. And from the moment you first contact us until your project is complete, we’re on call whenever you need a helping hand, 24/7, 365 days a year.

CUSTOM MATS

You describe your project, we’ll build a mat just for you. Whether you need special sizing, dimensions, strength rating or unique features, Global Mat has the experience and technology to manufacture customized mats for any application.

We’ve built custom mats for barge and ship decking, bridge building, ramps and turnouts, point load protection, rock concerts, special events, large vessel hauling and a host of other applications.

USED MATS

Global Mat is the leader in used mats with 100’s thousands in inventory throughout the United States. We are so confident in the lasting quality and prolonged value of our mats that we often repurchase our mats from customers (Buy-Back). Our used mats are cleaned and, if needed, minor repairs addressed. Then mats are graded into categories of A+, A, B, and C. We do not recommend older used mats for critical lift projects, however older mats are ideal in certain circumstances, such as being used in heavy wet soils as a bottom layer of a multi-layer project, at a fraction of the cost compared to new mats.

RENTAL MATS

With an annual output in excess of 250,000 units, Global mat is the leader in mat rental. All sizes are in stock for rapid delivery and can work in the harshest conditions from the jungles of Peru to -40° F in Northern Alberta, Canada.

Global Mat’s rent program is designed for the customer, in that we customize a plan to suit your needs with options to rent by day, week or month with substantial inventories of new and used mats throughout the world.

For more information on our products contact us at info@globalmatinternational.com or toll free at (800) 227-8159.